The Midtone Machines Chromabox film processor enters the production stage.

The Midtone Machines Chromabox film processor has entered the production stage. We talk to Andrew Burns who is the engineer behind the project.

By Christopher Osborne

I spoke to Andrew Burns who is the founder of Midtone Machines and the designer of the Chromabox film processing machine at his new premises. Parts have been steadily arriving at this airy industrial unit in leafy Auckland, New Zealand over the last two months. Eighty per cent of the required parts have been received, it is mainly sheet metal parts that are outstanding. Andrew has started assembling the first production machine and is carefully documenting the manufacturing process at each step. So while the assembly of this first example will take a little longer, it will pay off when producing than the remaining machines.

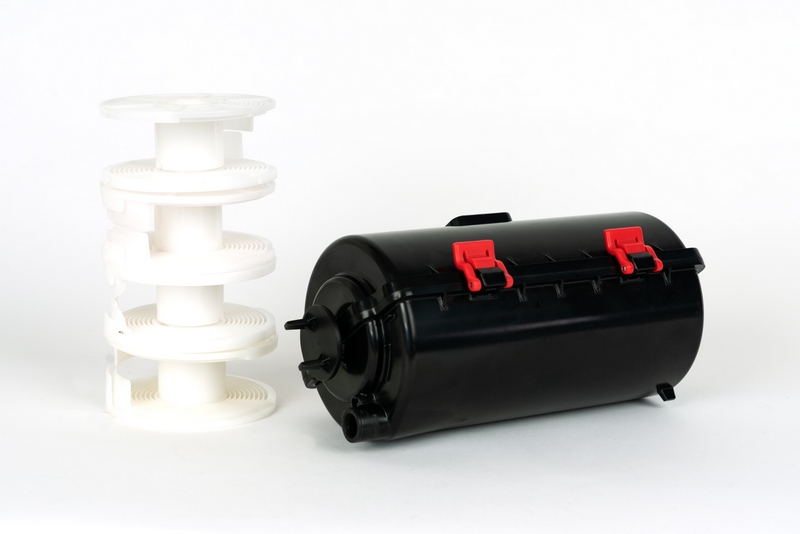

For those of you who are unfamiliar with the Midtones Machine Chromabox story, Andrew Burns is a rocket propulsion engineer. He is also a keen analogue photographer but doesn’t like developing film. He decided to create a machine that could automate the process. The machine holds electronic recipes that automatically warm the chemistry and pumps it in and out of a processing tank. This is a start & forget film processor.

To date, Andrew has made three pre-production machines and these have been processing film in labs in Auckland, Wellington and New York. “These machines have had a pretty harsh life”, Andrew says. “and they are all operating at the end of the trial period”.

He is currently finalising several modifications for the production version. “Many of these are to make manufacturing easier. Changes have relocated parts to reduce corrosion damage during accidental chemical spills. There are also ease-of-use design changes. For example, the temperature sensor cable that runs between the body and the tank is now held to the body with a magnetic clip so it can’t be accidentally damaged when removing the tank. And the SD card which holds the unit’s software is now accessible from the outside. This means that SD cards can be swapped between machines, which will be a handy feature for labs with multiple machines”, explains Andrew.

The current version uses Paterson reels, however, Andrew is investigating the practicality of a new spindle that would allow Jobo reels to be accommodated too.

“The target market for the Chromabox machine ranges from heavy use amateurs to processing labs. The machine will be perfect as the main machine for small labs. Larger labs are envisaged to use the machine for Black & White, E6 and ECN-2 and for C41 runs with non-standard development times to support customers who push or pull their film. These processes usually require smaller batch sizes”, says Andrew.

The current tank can handle sizes up to 5×7. Andrew is contemplating a tank version that can handle 8×10 inch film too. And he is already considering a second Pro version of the Chromabox that can handle a double-length tank. Other potential features include spacers that can be inserted into the tank to save chemistry, and WiFi connectivity so that larger labs can monitor and control the machines through a central web interface.

This current production run will be for 20 machines. Of these 12 are already earmarked for Freestyle in the US. One machine will be kept as a test bed and another will be used for CE certification.

Andrew is finalising distribution in other continents too. “It is important to have regional support”, says Andrew.

You can read more about the Midtones Machine Cromabox at their website https://www.midtonemachines.com/

Images © Andrew Burns 2022

You might also be interested in this SilvergrainClassics Fireside chat with Andrew Burns https://www.youtube.com/watch?v=c7M_VP9lkSw